Blog

In most homes, insulation and air sealing are the most effective ways to improve comfort and reduce heating and cooling costs.

This is part of a series; see the first post here.

This shouldn’t be news to anyone: In most homes, insulation and air sealing are the most effective ways to improve comfort and reduce heating and cooling costs.

This holds true regardless of heating systems or fuels used. So why is it emphasized even more when talking about heat pumps and electrification? Four reasons.

Say your home has a design heating load of 60,000 Btu/h.[1] If heating with fuel, you’ll need a furnace or boiler with a capacity of at least 60,000 Btu/h. These are easy to find. (In fact, you may have a hard time finding heating systems with capacities lower than this.) Air-source heat pumps, on the other hand, have smaller capacities. I don’t think you’ll find an ASHP with heating output of 60,000 Btu/h at cold winter temperatures. So to meet this load, you’ll need multiple ASHPs. And that gets pricey.

Even if you are not talking about multiple heat pumps, a 3-ton[2] heat pump is quite a bit less costly than a 5-ton heat pump. Costs of heat pumps scale more dramatically than costs of boilers and furnaces. So lower heating loads → fewer, smaller heat pumps → lower upfront costs.

If you have a boiler with baseboard convectors, water in those baseboards may be 150-180°F. Baseboards are located around the perimeter of a home, and warm air rising from these can offset the cooling effect from leaky windows and poor insulation. With a fuel-fired furnace, hot air is usually delivered in the 120-150°F range. As with baseboards, this hot air can counteract the effects of poor windows, drafts, etc.

Air-source heat pumps typically provide air in the 90-110°F range.[3] With lower supply temperature, you will need more air volume to meet the same load. Cooler supply air also may not counteract comfort problems from cold windows and drafts. With a good thermal envelope and lower loads, this lower supply air temperature is usually fine.

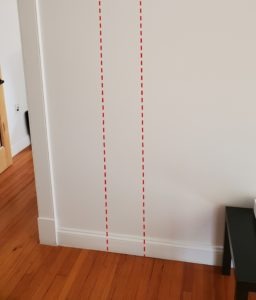

Because of the lower supply air temperatures of heat pumps, you need more air flow to meet the same load. If you’re planning to use existing ducts with a heat pump, there’s a good chance that the old ducts won’t be big enough to meet the heating loads many spaces. If you lower those loads (by insulating and sealing the enclosure), you may be able to reuse much more ductwork.

Reusing ductwork certainly saves money, but sometimes installing new ducts is intrusive, impractical, or nearly impossible within the scope of a project. Reusing existing ducts can be a big deal.

This benefit is pretty obvious: lower loads = lower heating costs. But there can be some nuance when comparing heat pumps to natural gas heating (which is relatively cheap these days).[4]

As no one wants to increase their heating costs, combining insulation and air sealing with switching from natural gas to ASHPs can result in lower overall heating costs. But when operating cost is the number one criterion for homeowners, I don’t see many switching from natural gas.

There are certainly other benefits to electrifying (see previous post). If you get heating loads very low, eliminating gas in the home altogether can make great economic sense. In a very efficient home, eliminating your monthly gas meter fees can outweigh the difference in the energy costs themselves. I count most new homes as “very efficient” in this regard; that’s why I think going all electric in new construction makes TONS of sense.

Note that the reasons for insulation and air sealing presented here hold true for hybrid systems[6] as well as heat-pump-only systems. Without insulation, for example, a heat pump may only provide comfort until outdoor temperatures drop to 35°F or so; then you’ll need to switch to backup. After insulation and sealing, the same heat pump may provide comfort down to 20°F.

Bottom line: if you’re considering electrifying your home, consider the envelope. If you’re a contractor that only installs HVAC, perhaps consider partnering with some insulation and air sealing folks. How to improve envelopes is beyond this post, but there are lots of good resources out there. BPA may be a good place to start.

Coming next: Step 3 – Calculate design loads accurately.

[1] It varies widely, but at typical residential rates in the Northeast in 2021, heating with natural gas generally costs less than meeting the same load with a heat pump.

[2] As always, IT DEPENDS. At the time of this writing (2021), good ASHPs cost less to operate than oil or propane at common energy prices in the Northeast US.

[3] It certainly can be higher, but that’s usually under more dramatic circumstances. Higher air temperatures lead to lower efficiency (sometimes dramatically lower), so normal operating temps are around 90-110°F.

[4] Hybrid: where heat pumps don’t do all the heating; fuel or electric resistance provides heat as well.

[5] 60,000 Btu/h is quite high for a single-family home. More in the upcoming load calculation post.

[6] 1 ton = 12,000 Btu/h. This goes back to refrigeration and the equivalent cooling capacity of a ton of ice. The term is still commonly used with air conditioners and heat pumps. It’s weird.

Robb Aldrich